-40%

EPOXY RESIN GASOLINE & DIESEL RESISTANT COATING SEALER & GLUE 4 FUEL TANK REPAIR

$ 31

- Description

- Size Guide

Description

MAX GRE A/BGASOLINE RESISTANT EPOXY SYSTEM

1/2 Gallon Of PART A -Resin

And

1 Quart Of PART B -Curing Agent

96 Fluid Ounce Combined Volume

PRODUCT

HIGHLIGHTS

Excellent Chemical Resistance

Superior Impact Resistance And Durability

Outstanding Adhesion To Metals And FRP Tanks

Prevents Rust And Oxidation

Gasoline Resistant Repair For Metal Tanks And Composite Fuel Cells

E85 Gasoline And Bio-diesel Blend

Secondary And Containment Linings

Impregnating Resin For Carbon Fiber & Fiberglass

Gasoline Tank Fabrication

DESCRIPTION

MAX GRE A/B is a two-part epoxy-based resin system (Bis A/Bis F Epoxy Hybrid) formulated for gasoline resistance. It is a premium grade resin system for repairs and restoration of metal fuel tanks that demonstrates excellent adhesion to metals, aluminum and other substrates used in fuel cells and tanks.

MAX GRE A/B is 100% solids and does not contain non-reactive components. MAX GRE A/B is resistant to swelling, softening, and loss of adhesion from immersion and direct contact to modern gasoline and diesel fuels. It demonstrates excellent dimensional stability and resistance to impact damage.

MAX GRE A/B is used as a barrier coating for metal and FRP fuel cells. It provides a high degree of chemical-resistance against petroleum-based gasoline, diesel, and ethanol fuel blends (E85).

MAX GRE A/B is an anti-corrosion coating for steel substrates, and prevents oxidation on aluminum and copper metals.

MAX GRE A/B works well as an impregnating resin for fiberglass, carbon fiber fabrics for patching, reinforcing and fabricating FRP composite fuel cells. MAX GRE A/B is used as a strong adhesive for bonding metals, FRP composites, and most porous substrates.

Surface Preparation For Metal Tank Repair

The metal substrate must be cleaned appropriately to remove oily residue by chemical degreasing. Remove and loose or flaking rust, and for the best adhesion performance, abrade or sandblast the surface to bare metal, so the MAX GRE A/B coating is in direct contact with the metal substrate. Use acetone or alcohol to degrease the surface and ensure that the substrate is dry and free from contamination before application.

For aluminum substrates, chromic acid etching is recommended for bonding and coating.

Testing Surface Wettability

Why Epoxy Coatings Beads-up And Separate. Testing And Surface Preparation Before Epoxy Application. - YouTube

Video will open in a new window

Using the eBay App? Paste link into a browser window:

[isdntekvideo]

Precaution: As with industrial chemicals of the same nature, avoid direct skin contact using protective gloves and eyewear. Ensure the work area is well ventilated when working with flammable fuels. Extinguish any flame source to prevent fuel vapors accidental ignition. Always practice safety first.

MAX GRE A/B is mixed 2:1 by weight or by volume and offers a 35 to 45 minute working time. Use a scale to measure the proper mix ratio accurately, which dramatically affects cured chemical resistance, especially when mixing small batch sizes. The mixed consistency is similar to cooking oil. MAX GRE is self-leveling and will continue to flow until the MAX GRE resin gels or converts to a solid.

As a coating, apply the MAX GRE using a brush or roller coat. The ideal coating thickness to create a hermetic barrier is 0.015-inch or 15 mils and may require several applications to achieve the target coating thickness. Allow the first coat to cure for 5 to 6 hours at 75°F and repeat the application directly on top of the previous application. Once the desired thickness is achieved, allow the MAX GRE to fully cure 36 to 48 hours at 25°C to 30°C before use.

To use the MAX GRE as an adhesive, prepare the substrates to its bare condition so the MAX GRE is directly applied and in full contact with the base substrate. Ensure bond foot-print is relative to the amount of force that is expected. Mix the proper amount of the resin and curing agent for the application. Bondline control media such as ‘Potter’s Glass Bead’ is typically mixed with the MAX GRE to meter the ideal bondline thickness of 5 to 7 mils. Apply the mixed MAX GRE on both substrates to be bonded and assemble. Apply sufficient clamping force to ensure both substrates are mated. Allow to fully cure for 36 to 48 hours at 25°C to 30°C before use.

MAX GRE also works well as a potting compound for encapsulating fuel level sensors. It is suitable up to a ¾-inch thick casting or embedding. Upon cure, MAX GRE is non-conductive and provides electrical insulation for low voltage signals for gauges and meters. MAX GRE bonds well to copper wires and holds connections in place. It is resistant to pull-outs from expansion and contraction coefficients and mechanical vibration from average use and environment.

As an impregnating resin for composite fabrication, use silane or volan treated fabrics for the best epoxy resin compatibility and wet-out. Saturate the fabric with the MAX GRE at 33 percent resin content. Allow to fully cure for 48 hours at 25°C to 30°C before use. Observe composite fabricating guidelines for making fuel cells.

Cured MAX GRE Specimens in E85 Gasoline Continuous Immersion Test

HARDNESS TEST AFTER 30 DAY IMMERSION

Testing the Durometer Hardness of the specimens determines if the cures resin is being affected by the gasoline immersion. The weights and Durometer Hardness of the specimens were measure before and after the immersion test and any changes in weights and hardness are measured.

After several years of continuous gasoline immersion, the MAX GRE test specimens exhibited excellent Shore hardness retention and weight stability demonstrating its excellent chemical resistance.

Testing Weight Change After Prolonged Gasoline Immersion.

Negligible Change In Weight (Less Than 0.03%) Measured, Demonstrating Excellent Gasoline (E85 Grade) Resistance.

Starting from June 2009 to February 2020, specimens have been fully immersed in gasoline and has shown no appreciable change in dimension, weight, and durometer hardness.

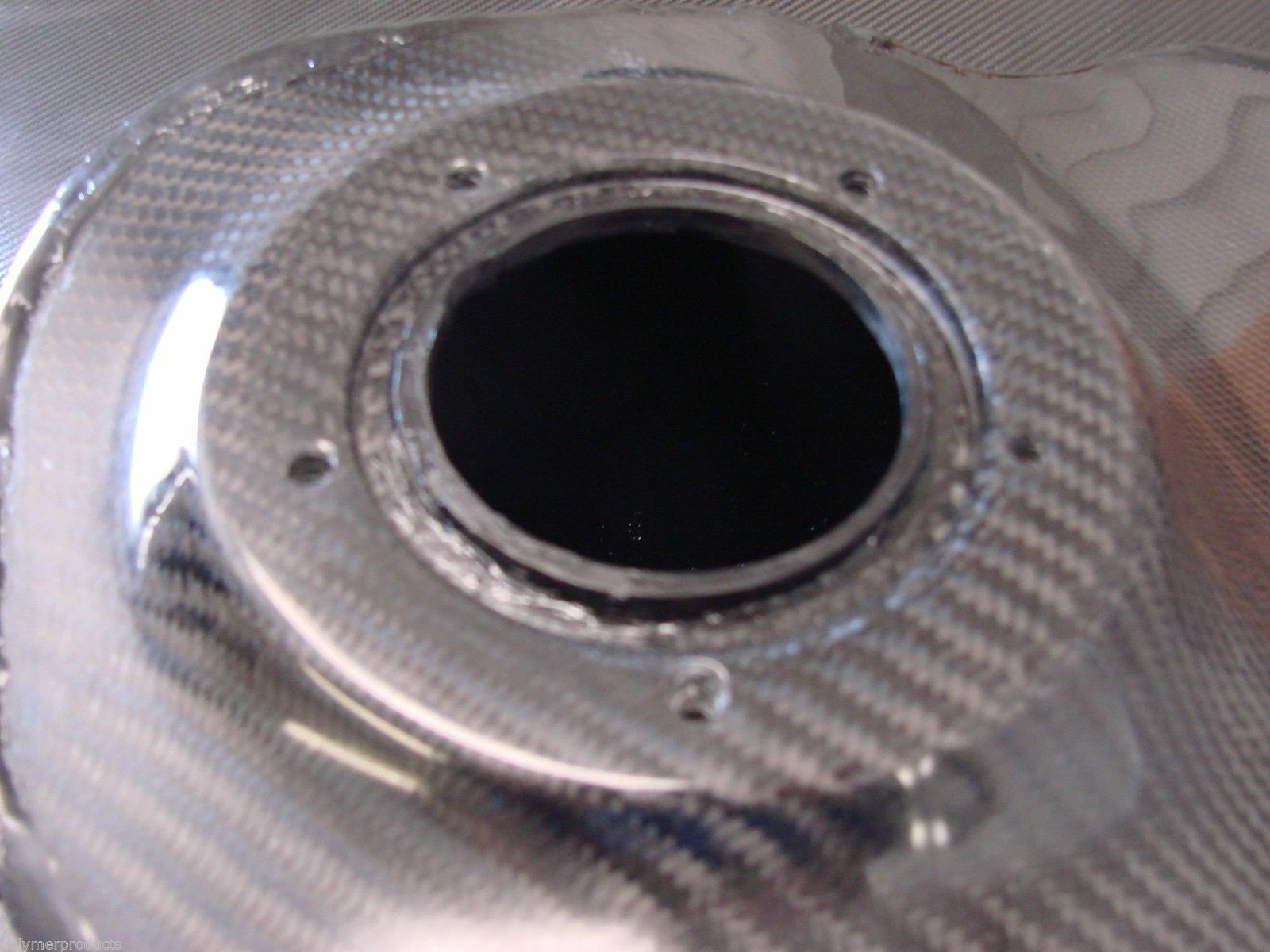

Customer Refurbish And Repaired Gasoline Tank With MAX GRE A/B

Surface Preparation, Fiberglass Patch Rust-Through

Cavity Repair And Integral Sealing of Metal Tank

Compliments Of Jeff @ElderyIron

Click On The Image To View The Video Demonstration

Repairing a Gas Tank with Gasoline Resistant Epoxy 1981 Dodge Colt - YouTube

Video will open in a new window

Using the eBay App? Paste link into a browser window:

[isdntekvideo]

Click On The Image To View The Video Demonstration

Prepping the Obsolete 1981 Dodge Colt Gas Tank For Repair - YouTube

Video will open in a new windowxxxxx

PHYSICAL PROPERTIES & MECHANICAL PROPERTIES

Density

1.10 G/CC

Form and Color

Clear Liquid

Viscosity

2500-3000 cPs @ 25ºC Mixed

Mix Ratio

2:1

100 Parts “A” to 50 Parts “B”

Working Time

45 – 50 Minutes @ 25

°

C

(100 Gram Mass)

Peak Exotherm

70°C (100 Gram Mass)

Thin Film Set Time

4 to 6 Hours

Handle Time

8 Hours

Cure Time

2 to 7 days @ 25°C

Accelerated Cure Time

8 hours at room temperature plus 1 hours at 100

Hardness

80 ± 5 Shore D

Tee-Peel Strength

3.4 Lbs. per inch Width

Tensile Shear Strength

2,935 psi @ 25°C

1,970 psi @ -40°C

1250 psi @ 100°C

Elongation

3.0% @ 25°C

Flexural Strength

13,000 psi

Flexural Modulus

344,000 psi

Heat Deflection Temp.

70°C

CHEMICAL RESISTANCE PERFORMANCE

FULL IMMERSION

at 30°C

MEASURED PERCENT CHANGE IN WEIGHT

REAGENT

10 days

28 days

Deionized Water

0.09 %

0.03 %

Sea Water

0.01 %

0.08 %

Methanol

3.93 %

Destroyed

Ethanol

1.98 %

1.82 %

Toluene

0.40 %

2.86 %

Xylene

0.24 %

2.55 %

Gasoline (E85 Blend)

0.10 %

0.03 %

MEK

2.96%

Destroyed

10% Lactic Acid

1.81 %

5.42 %

10% Acetic Acid

0.11 %

0.45 %

70% Sulfuric Acid

0.08 %

0.14 %

50% Sodium Hydroxide

0 %

0.1 %

10% Sodium Hypochlorite

0.51 %

1.36 %

USE AN INFRARED HEAT LAMP FOR CURING LARGER PARTS

MIXING AND USAGE APPLICATIONS

Please View The Following Video Demonstration Of The Proper Mixing Of Epoxy Resins.

The Resin And Curing Agent Must Be Mixed To A uniform Consistency To Eliminate Tacky Or Uncured Spots.

THE USE OF A WEIGHING SCALE IS HIGHLY RECOMMENDED

Purchase this scale with any of our offering &the shipping cost of the scale is free.

https://www.ebay.com/itm/222630300203

EVIDENCE OF POOR MIXING

Click On The Image To View The Video Demonstration

Mixing epoxy resins -2 cup method - YouTube

Video will open in a new window

[isdntekvideo]

EPOXY RESIN MIXING TECHNIQUE

Click On The Image To View The Video Demonstration

How To Mix Epoxy Resin For Food Contact Coating. Avoid Tacky Spots, Minimize Air Bubble When Mixing - YouTube

Video will open in a new window

Using the eBay App? Paste link into a browser window:

[isdntekvideo]

AIR BUBBLE REMOVAL TECHNIQUE

Click On The Image To View The Video Demonstration

HOW TO REMOVE AIR BUBBLES FROM EPOXY COATING

Video will open in a new window

[isdntekvideo]

AVOIDING EXOTHERMIC RUNAWAY REACTION

Click On The Image To View The Video Demonstration

BASIC EPOXY RESIN USAGE AVOIDING EXOTHERMIC RUN AWAY REACTON - YouTube

Video will open in a new window

[isdntekvideo]

Best Style Fabric For Patching -

Use A Satin Weave Style Fiberglass Fabric That Offers Excellent Draping Over Curved And Corners

https://www.ebay.com/itm/223385247088

*************************

PLEASE CHECK OUT OTHER AVAILABLE

RESIN SYSTEMS AT OUR eBay STORE

For our complete listing, please

Visit our eBay store!

DON'T FORGET OUR EPOXY MIXING KIT

Click The Link To Add To Order

https://www.ebay.com/itm/222623932456

EVERYTHING YOU NEED TO MEASURE, MIX, DISPENSE & APPLY

Proportioning the correct amount is equally as important to attain the intended cured properties of the resin system.

T

he container in which the epoxy and curing agent is mixed is an important consideration when mixing an epoxy resin system.

The container must withstand the tenacity of the chemical and must be free of contamination.

Most epoxy curing agent has a degree of corrosivity, as a general practice, protective gloves should be worn when handling chemicals of the same nature.

MIXING KIT CONTENTS

1 Each Digital Scale -Durable, Accurate Up To 2000.0 Grams

4 Each 32-ounce (1 Quart) Clear HDPE Plastic Mix Cups

4 Each 16-ounce (1 Pint) Clear HDPE Plastic Mix Cups

One Size Fits All Powder-Free Latex Gloves

2 Each Graduated Syringes

Wooden Stir Sticks

Chip Brush

IMPORTANT NOTICE

Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product.

The user should thoroughly test any proposed use of this product and independently conclude the satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval.

The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, PolymerProducts and Polymer Composites Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use.

There is no warranty of merchantability for fitness of use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. PolymerProducts and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.